select your product-group:

Please select your preferred machining method based on the features listed below:

(please note that there might be some issues with the internet explorer - we recommend using any other browser)

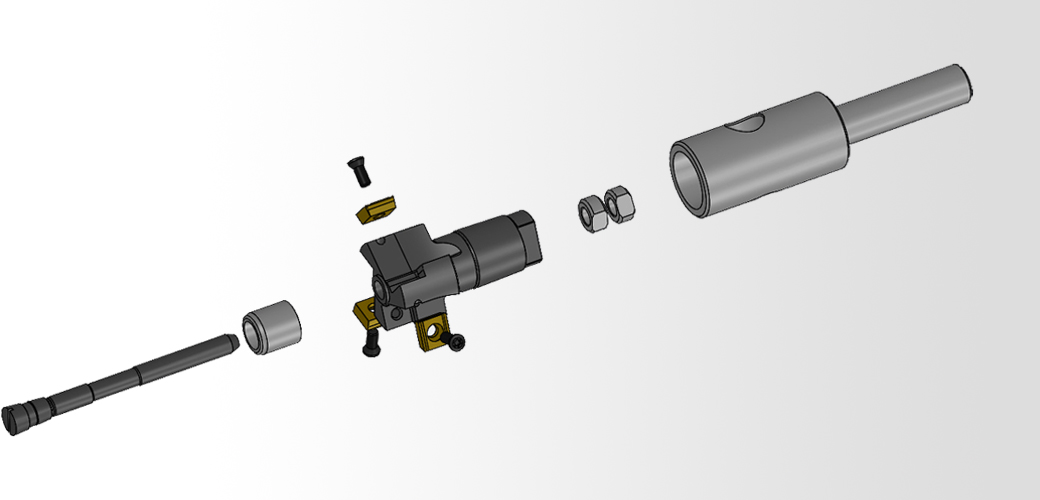

TU-System

back countersink

- individually customizable also for intermediate sizes

- manually operated reverse machining

- universally applicable on all machine types

- flexible handling for small production batches

- for spotfacing and counterboring

- large cutting width up to 2.5 times the boring diameter

- several diameter combinations of counterbores and holders possible

- flat bayonet for quick and reliable manuel tool changes

- multiple regrinds are possible

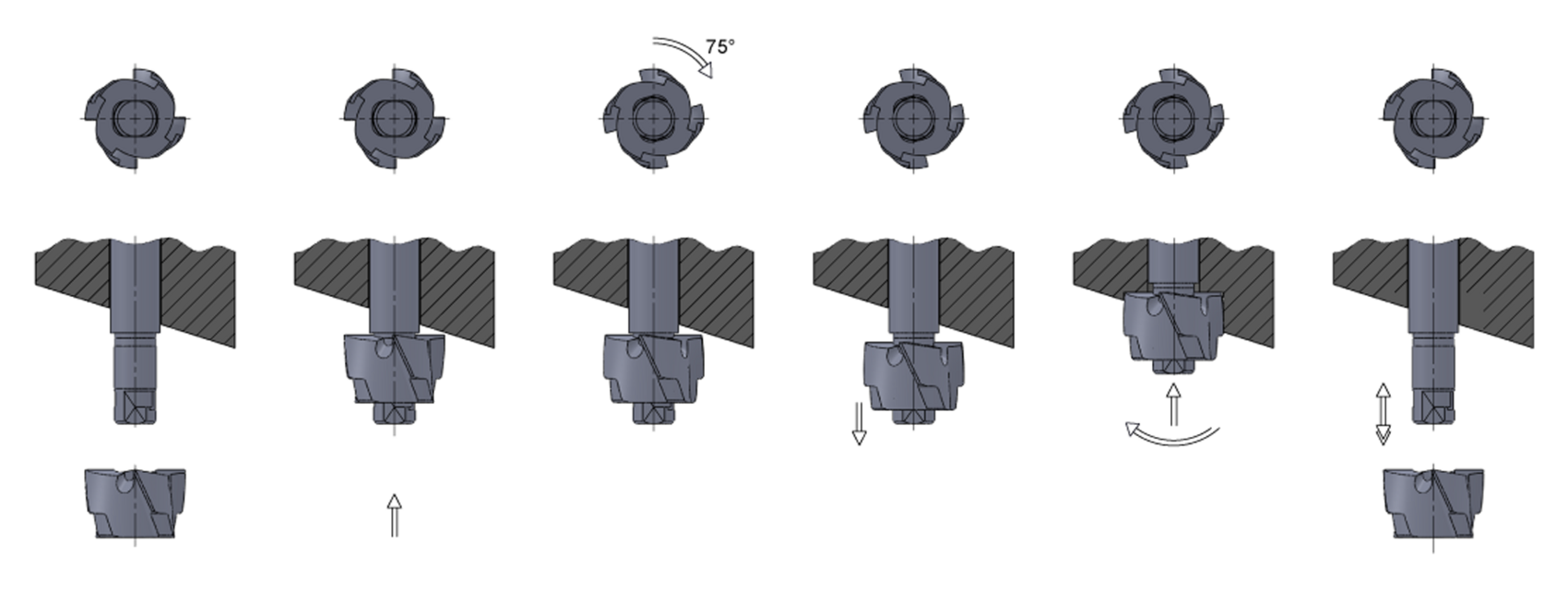

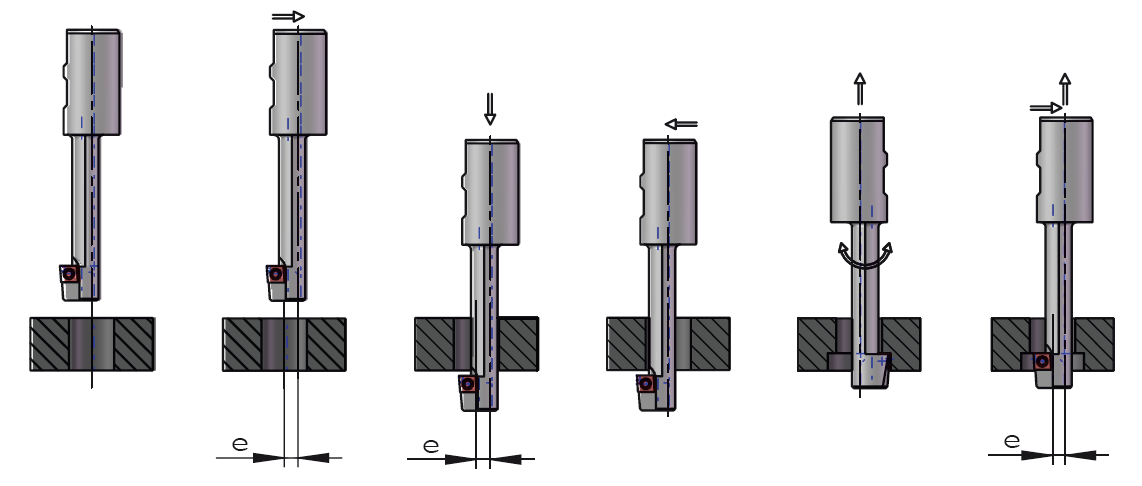

R5B / RBU / RBSM

Reverse boring bar

- automatic machining for medium to large production batches

- for spotfacing, chamfering and deep counterboring of areas with difficult access

- for counterboring up to 1.9 times the boring diameter

- usable for many materials due to a wide choice of different PCD-, carbide- and HSS-indexable inserts

- internal coolant for RBS+ starting from Ø18

- RBU offers a much higher stability due to optimized cutting edge position

- large E-modulus of solid-carbide RBS-Micro (RBSM) ensure max. stability

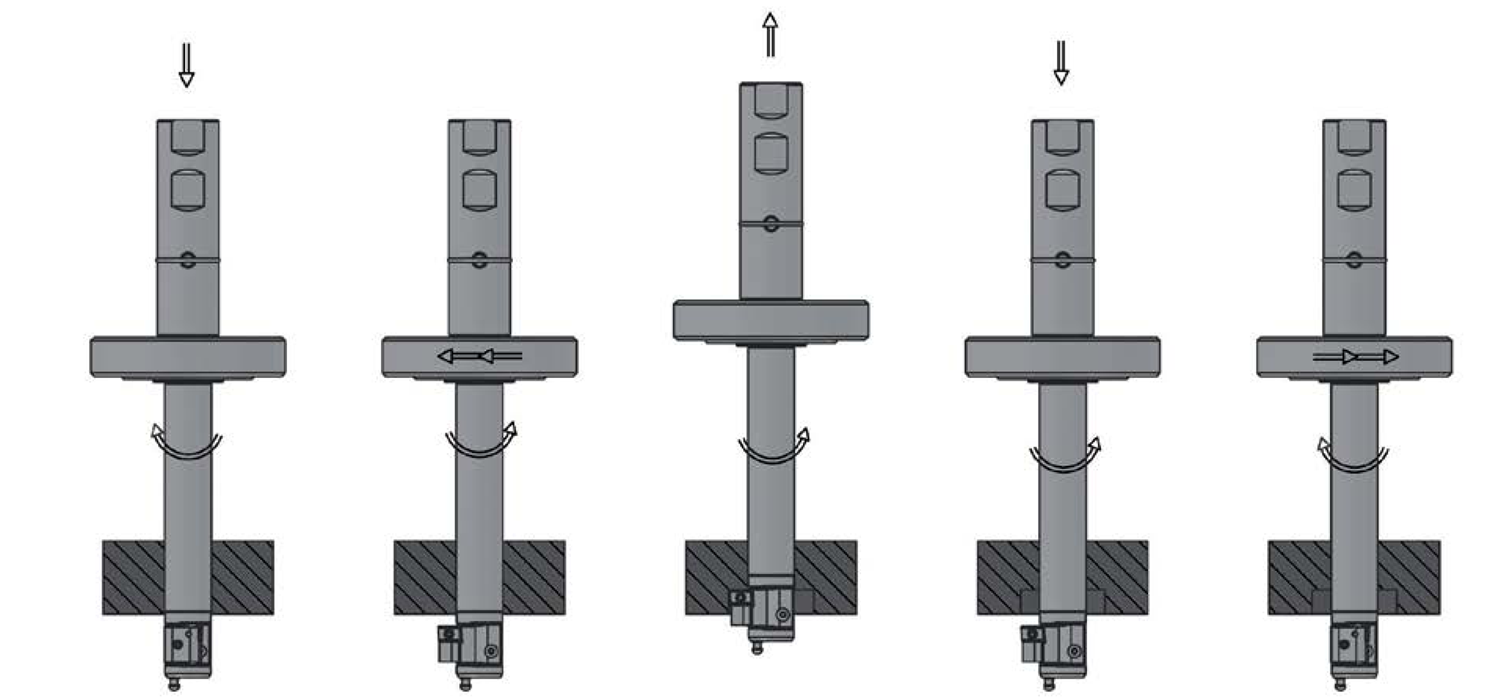

Autofacer

AFA

- customized special design according to your needs

- automatic machining for mass-production

- high reliablility and safety

- forward and backward machining possible

- large cutting width up to 2.3 times the boring diameter

- Autofacers are designed individually for each specific application

- lean design avoids collisions