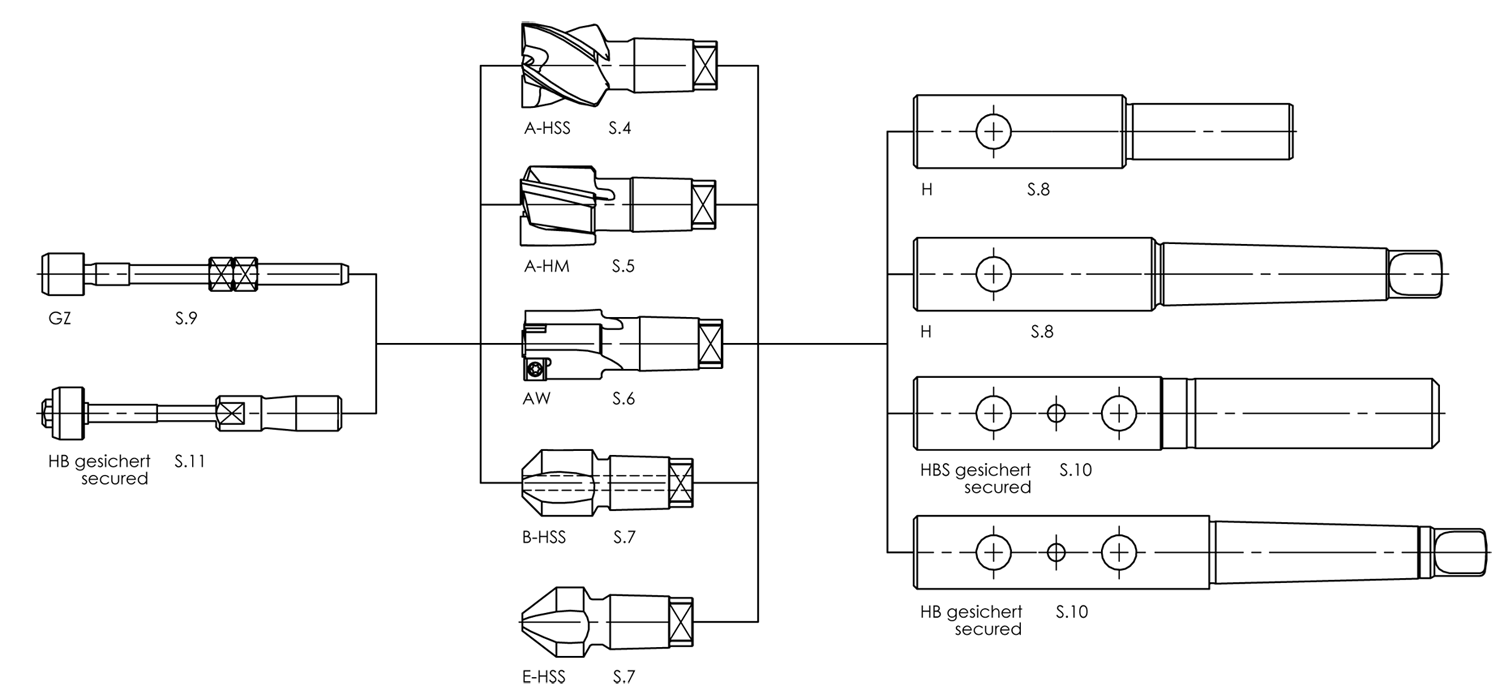

Product Selector: Counterbore

Select your product-group:

Please select your preferred machining method based on the features listed below:

(please note that there might be some issues with the internet explorer - we recommend using any other browser)

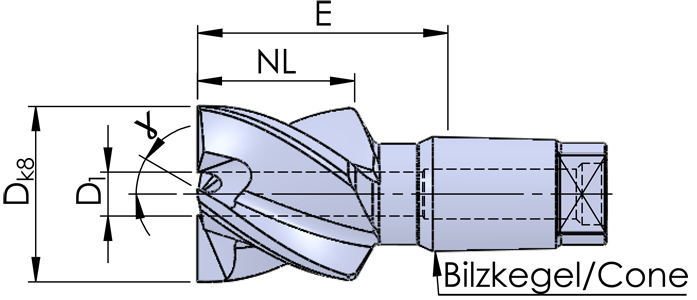

Bilz-counterbore A-HSS

- Particularly suitable for spotfacing and counterboring of screw head counterbores in tough steel- , aluminium- and copper-alloys up to about 800 N/mm²

- Three respectively four cutting edges (D>=18) with rake angle 25° respectively 30° offer high stock removal rates at low cutting forces

- Long tool life due to multiple regrindability

- Universally usable on many kinds of machine tools with and without rotating pilot

Bilz-counterbore variation 3-HSS:

- for hardened tough and brittle materials (Rm > 800 N/mm²)

- rake angle γ= 18°

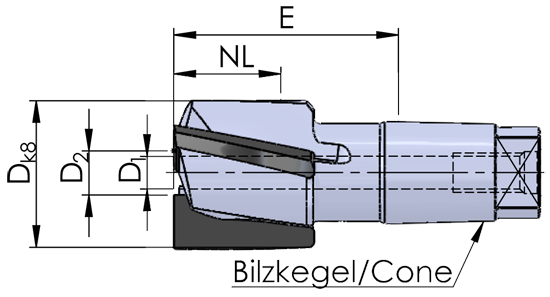

Bilz-counterbore A-HM

- For hard and tough, brittle and short-chipping materials like grey cast iron, brass and aluminium

- Three cutting edges with rake angle 8° respectively 12° (D>=9)

- Fine-grain carbide with high wear resistance

- Long tool life due to multiple regrindability

- Universally usable on many kinds of machine tools with and without rotating pilot

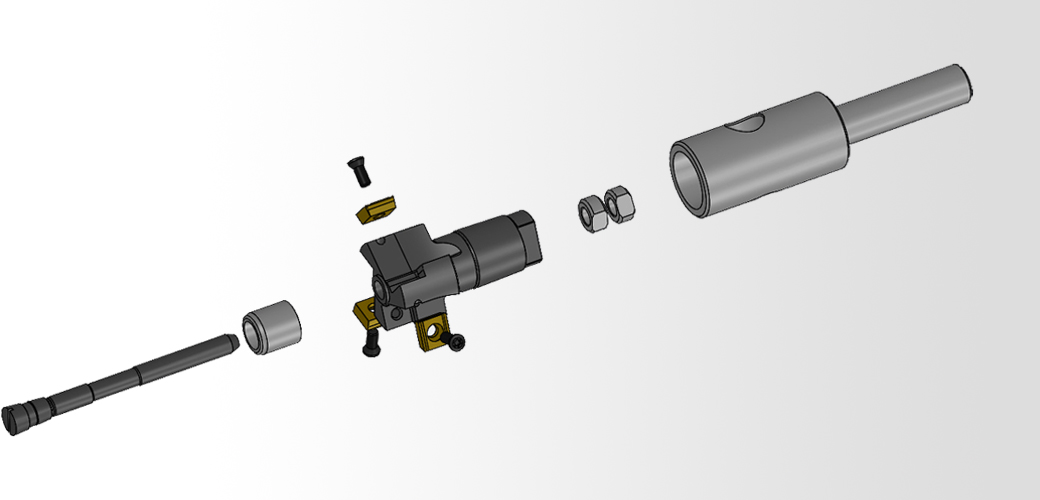

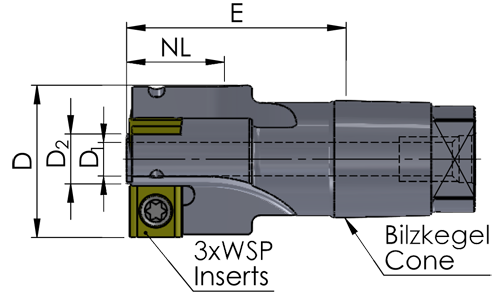

Bilz-counterbore AW

- Particularly suitable for spotfacing and counterboring of screw head counterbores in all kind of material

- Three insert seats for carbide-, cermet- and HSS-E-Inserts with different geometries and coatings

- Round ground guiding chamfers on the inserts (...Z...) prevent chattering, burnish the bore surface and allow close tolerances (IT9-11)

- Universally usable on many kinds of machine tools with and without rotating pilot