Hermann Bilz PCD tools: Customised solutions for your application

Hermann Bilz GmbH & Co KG has been a manufacturer specialising in customised special solutions in the field of precision tools for many years. The focus is not on mass-produced products, but on tools that are individually customised to the respective application, which can also be equipped with polycrystalline diamond (PCD) if required. These customised tools offer a unique combination of precision, efficiency and flexibility and are used in demanding manufacturing processes.

Individual challenges require customised solutions

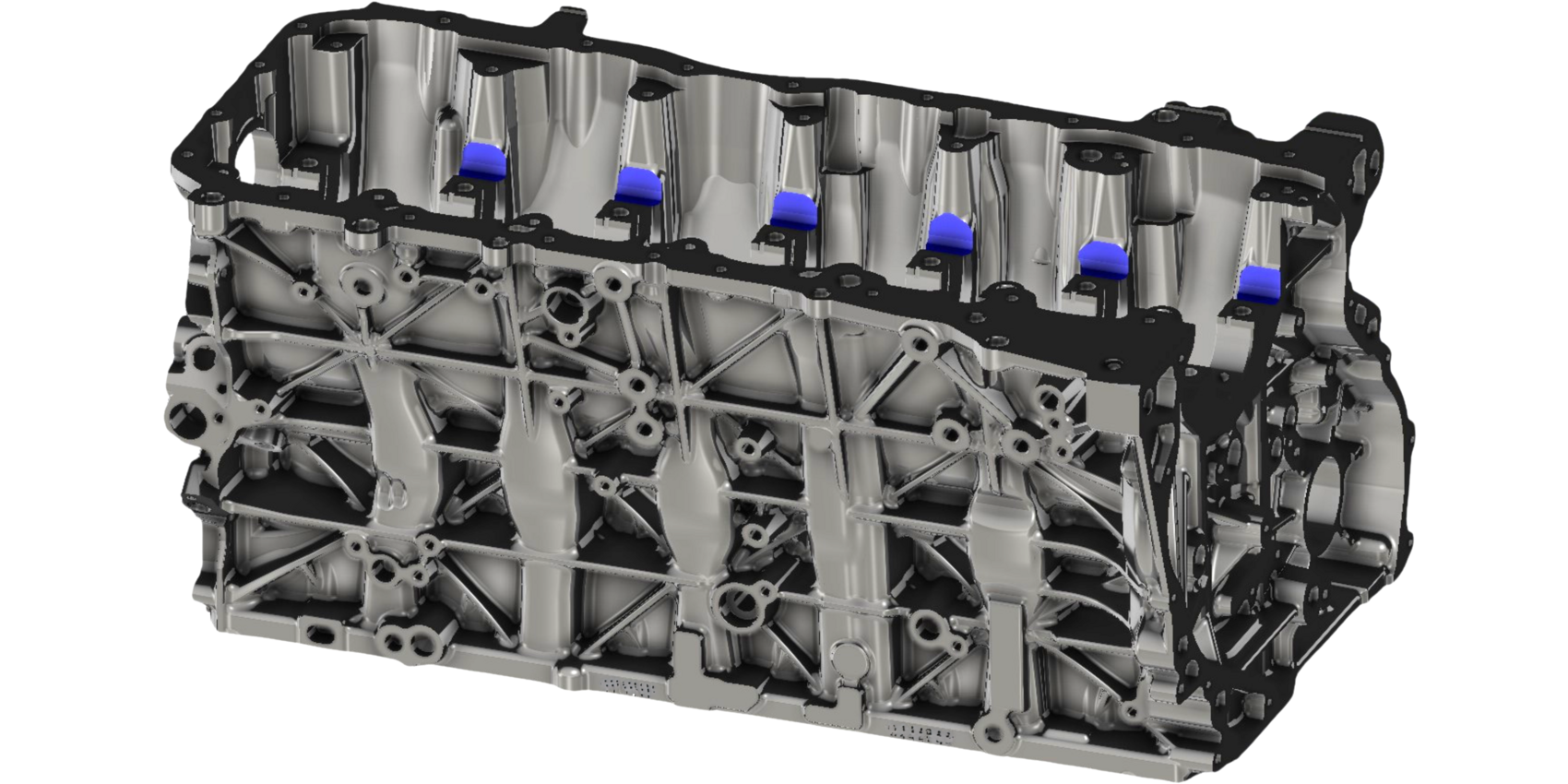

Modern metal machining is characterised by increasing demands: Maximum precision, flexibility and cost-effectiveness are essential in order to remain competitive. The specific requirements of customers demand customised tools, particularly for complex machining operations such as milling bearing grooves in engine blocks or creating recess contours for camshaft bearings in the cylinder head.

Hermann Bilz develops and manufactures customised PCD tools for each of these applications, which are precisely tailored to the needs of the respective production. The company does not offer standard PCD solutions, but tools that are optimised for the customer's specific application conditions.

The part and the challenge

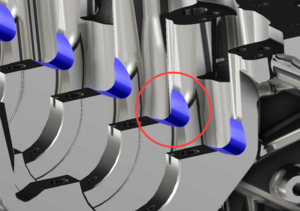

When manufacturing engine blocks, milling the bearing groove contour is one of the greatest challenges, as maximum efficiency and ease of servicing are required here. Hermann Bilz offers a customised solution in the form of bearing groove milling cutters that are equipped with replaceable and resharpenable cassettes. This enables flexible use and reduces the need for replacement tools, which significantly increases the efficiency of the machining process.

The Bilz solution

Advantages that impress!

- Quick and easy replacement of cutting cartridges

- Tool can be used again immediately after cartridge replacement

- No replacement tools required as with monoblock cutters

- No waiting time for reconditioning as with monoblock cutters

- PCD cartridges can be resharpened

(Kopie 6)

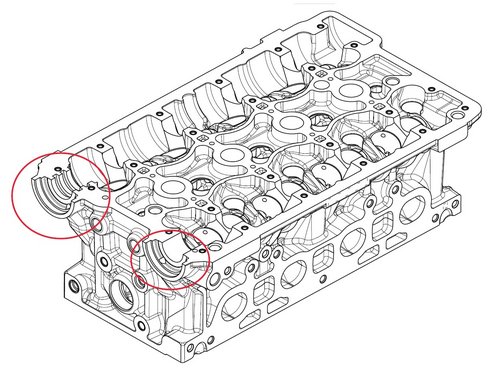

The part and the challenge

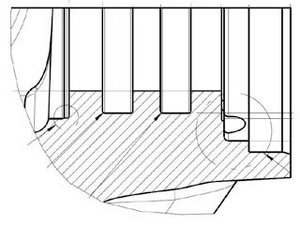

The precise machining of the groove contours for the camshaft bearing in the cylinder head requires specialised tools in order to machine different contours in a single operation. The PCD-tipped groove milling cutter developed by Bilz with 4 to 6 cutting edges per step is specially designed to fulfil these complex requirements. The high number of cutting edges ensures consistent and fast machining, which significantly reduces production time.

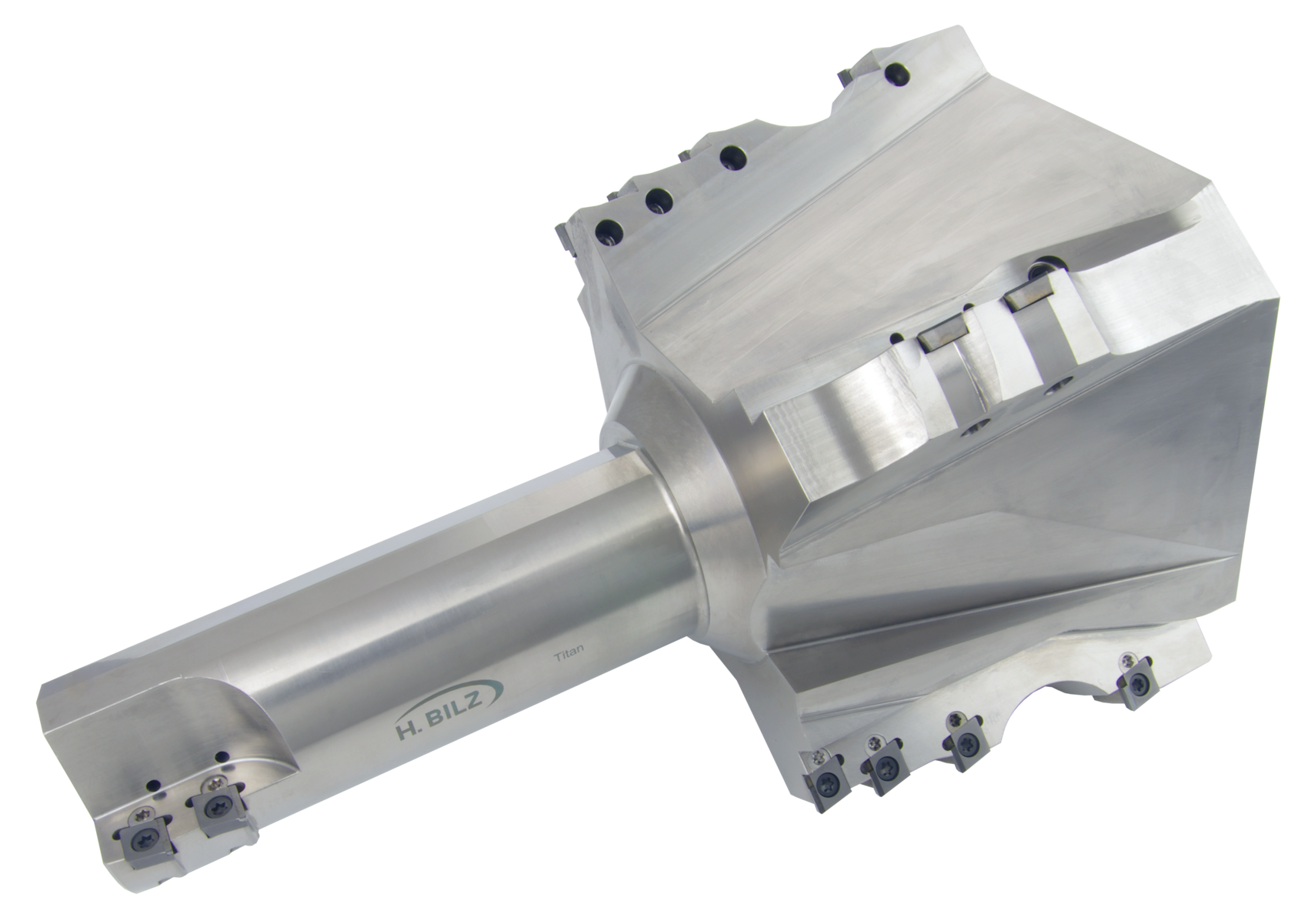

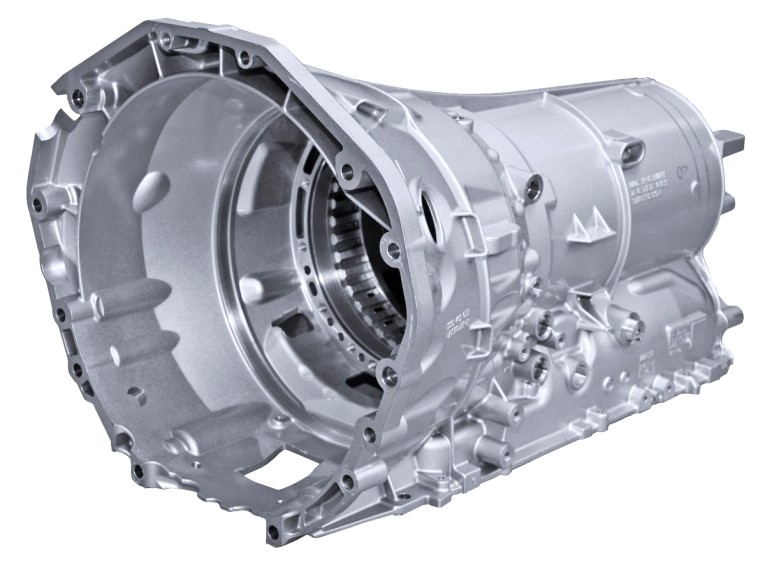

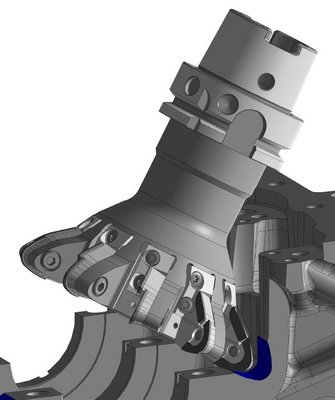

Indexable insert boring tool

Bilz offers an indexable insert boring tool with adjustable PCD indexable inserts for the forward and backward machining of gearbox housings. The basic body of the tool is made of lightweight titanium, which facilitates handling and reduces the load on the machine. The flexible adjustability of the indexable inserts makes it possible to combine different machining steps in one tool, thereby optimising production processes.

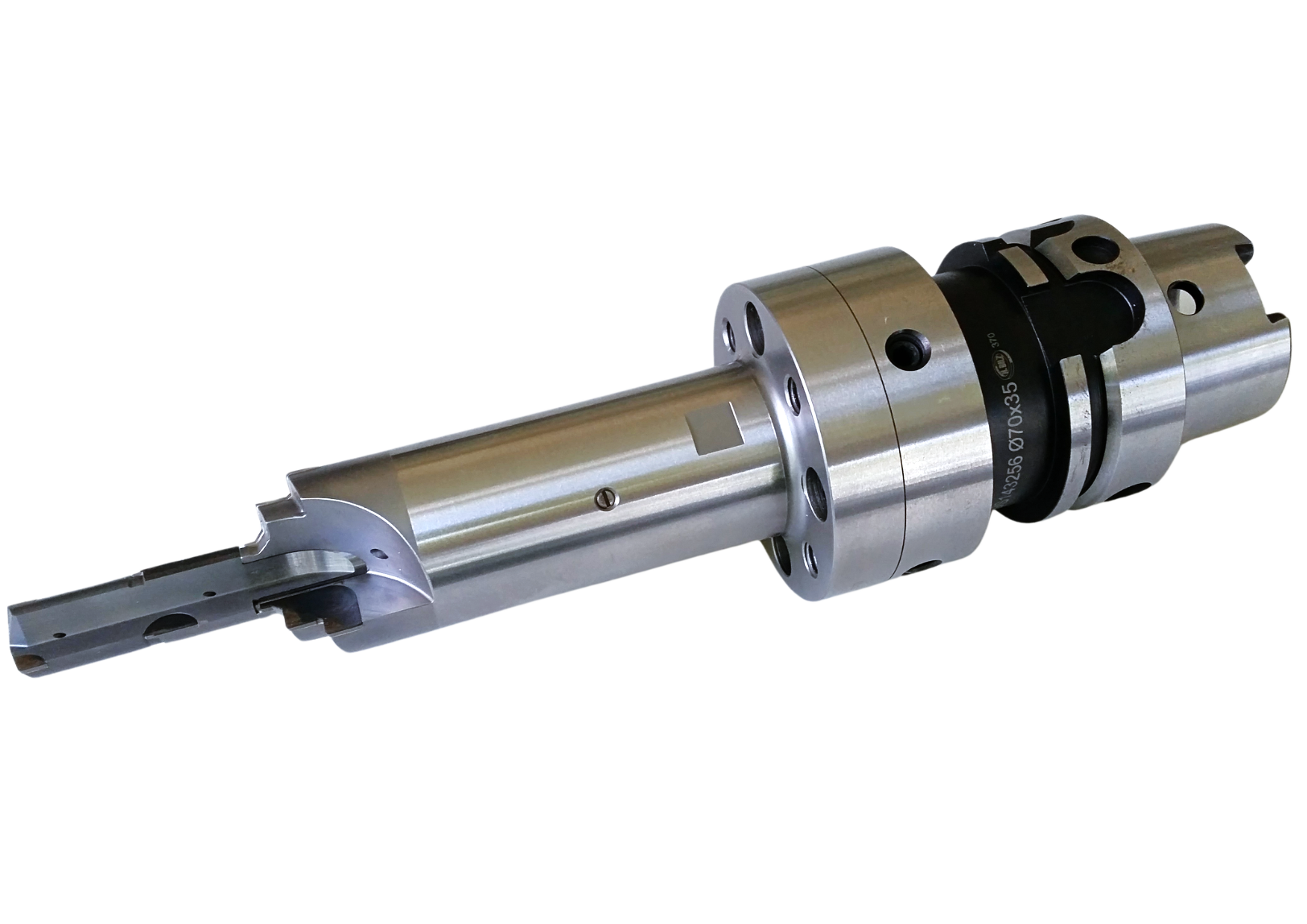

Drilling and countersinking combination

This tool combines a PCD-tipped solid carbide step drill and a countersink equipped with a flange holder for concentricity adjustment. This combination makes it possible to carry out drilling and countersinking work in a single operation. This minimises the machining time and increases accuracy, which is particularly advantageous when machining light metals.

Step reamer

The Bilz stepped reamer, equipped with 4 or 6 PCD cutting edges, is specially designed for finishing both connecting rod eyes. Thanks to the high number of cutting edges, tight fits and a smooth surface quality can be achieved in a single step. This makes the reamer the ideal solution for applications where maximum precision and efficiency are required.

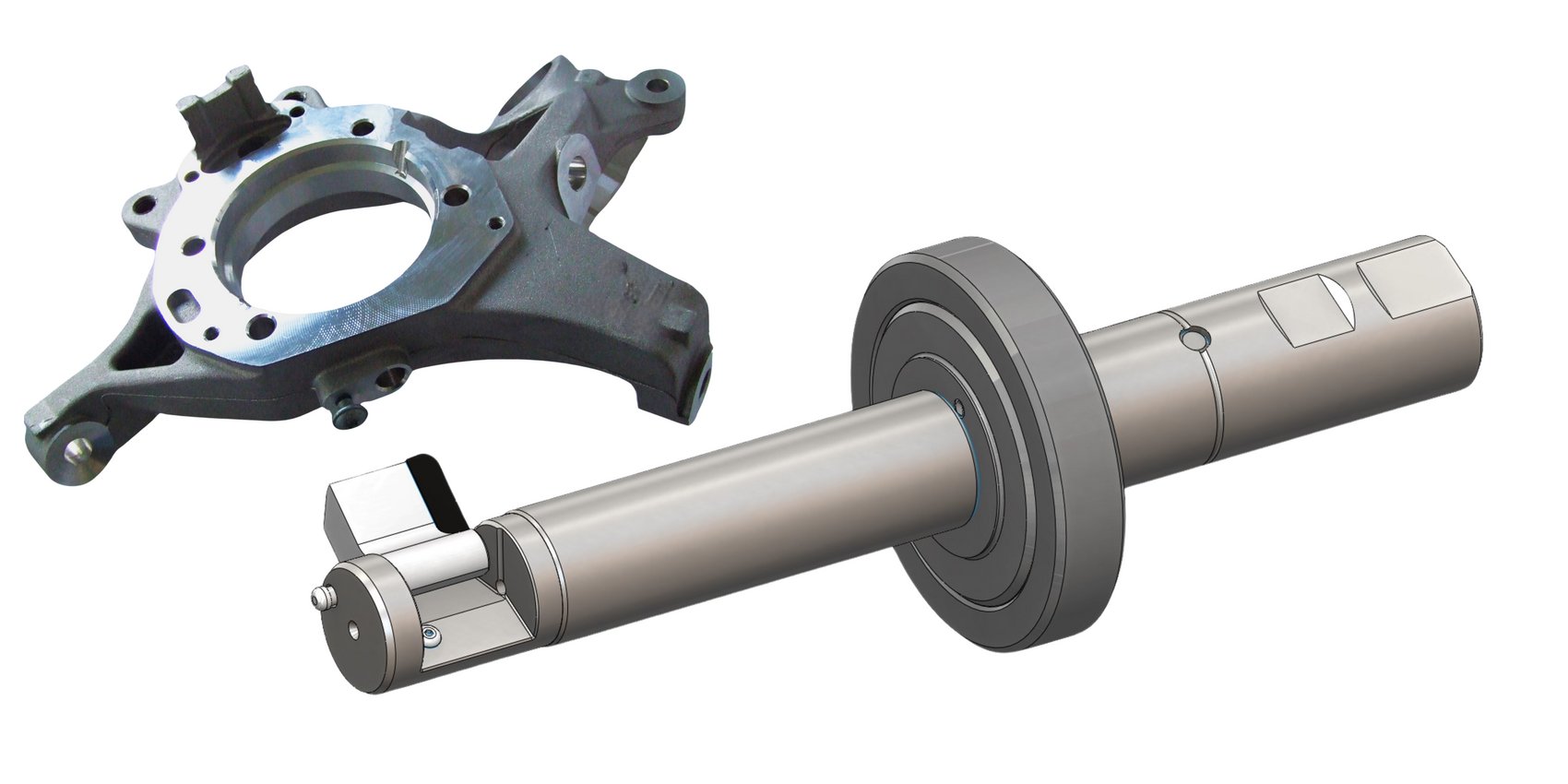

Autofacer

The Autofacer is designed for the fully automatic reverse machining of wheel carriers and enables precise machining of hard-to-reach areas. This tool is characterised by its high level of automation, which not only reduces the amount of work required, but also ensures consistently high machining quality.

The advantages of customised PCD solutions from Hermann Bilz

The customised PCD tools from Bilz offer decisive advantages over standard tools:

- Individual customisation: each tool is specially developed to meet the requirements of the specific application. This ensures the highest precision and maximum efficiency.

- Short delivery times for customised solutions: Despite customisation, Bilz offers fast response times and short delivery times. After technical clarification and order confirmation, delivery usually takes place within two to five weeks.

- High efficiency and durability: PCD cutting edges offer an extremely long service life, and the option of resharpening the cutting cartridges further extends the service life of the tools.

Speed and precision - Bilz remains flexible

Bilz not only offers customised tools, but also ensures that customers are supported quickly even in the event of urgent requests. With a large range of tools in stock and flexible machinery, Bilz can react immediately in emergencies and adapt or manufacture new tools.

In addition, the company guarantees µ-precision in production in order to fulfil even the highest requirements for fits and surface qualities. This precision and flexibility make it possible to avoid additional work steps and thus save time and costs.

Conclusion: Customised PCD solutions for maximum efficiency

Hermann Bilz GmbH & Co KG has established itself as a reliable partner for customised precision tools. Thanks to the combination of PCD cutting, innovative solutions and fast delivery times, companies in a wide range of industries can organise their production processes more efficiently and increase quality at the same time.

We would like to invite you to see Bilz's customised solutions for yourself. Contact us today and let us advise you on how a PCD tool individually tailored to your needs can optimise your production processes.